SHEAR SPEEDSTER - DEVELOPMENT

COMMISSION BUILT SPECIALTY CARS TAILOR- MADE FOR EACH INDIVIDUAL |

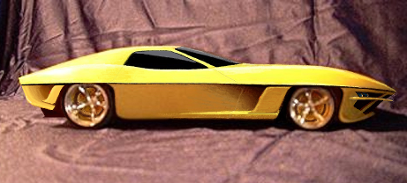

SCALE MODEL

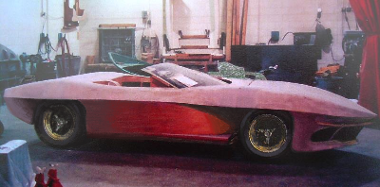

FULL SCALE PATTERN

COMPOSITE , ALUMINUM, and STEEL FRAMES AVAILABLE

WE BUILT THE PATTERN OUT OF WOOD MAINLY BECAUSE IT WAS THE LEASE EXPENSIVE AND EASIEST MATERIAL TO WORK WITH. TRADITIONALLY WHEN WE HAVE BUILT FIBERGLASS BOAT MOLDS, WE BUILD A WOOD PATTERN/PLUG MUCH LIKE BUILDING A WOOD BOAT. THEN WE USE FILLERS , POLYESTER PRIMERS, AND LOTS BLOCK SANDING TO CREATE OUR SMOOTH SURFACE. A COATING OF P.V.A. (polyvinyl alcohol) BEFORE STARTING TO BUILD THE MOLD. YES, THIS OLD FASHION WAY IS LABOR INTENSIVE AND IS ONLY AS ACCURATE AS THE HANDS THAT BUILD IT. ( and this pattern is very accurate !) AS FAR AS SPEED, AS IN HOURS OF LABOR, THIS OLD SCHOOL WAY OF DOING THINGS DOES NOT HAVE AS MANY HOURS IN IT AS YOU MAY THINK. A 5-AXIS MILL WOULD BEAT MY TIME, BUT IF YOU PRICE OUT THE COST OF CAD-CAM DESIGNING, THE COST OF MATERIALS TO BE MILLED, AND OF-COURSE THE COST PER HOUR OF MACHINING USING A VERY HIGH $ TOOL. NOW YOU HAVE A VERY EXPENSIVE PATTERN, YOU STILL NEED A MOLD. THEN THE PARTS OUT OF THE MOLD. YOU COULD HAVE THE 5-AXIS MILL JUST MILL OUT A ALUMINUM MOLD , ALSO VERY HIGH $ BUT IT IS DURABLE . THIS ALL WORKS GREAT FOR SMALL PARTS OR FOR LARGE COMPANIES WITH BIG $ THAT PUMP OUT 1000's OF PARTS PER DAY/ OR PER MINUTE. OTHER POSSIBILITIES INCLUDE MILLING OUT A TEMPORARY MOLD FROM THE SAME HIGH DENSITY FOAM THAT WOULD NORMALLY BE USED AS THE PATTERN. IT IS STILL COSTLY, BUT YOU SAVED SOME MONEY BY SKIPPING A STEP! DEPENDING ON YOUR BUDGET, WE CAN BUILD YOUR DREAM CAR USING LOW-TECH PROCEDURES OR USE SUBCONTRACTED HIGH-TECH PROCEDURES FOR ANY STAGE OF YOUR PROJECT. THE IMPORTANT THING TO REMEMBER IS THAT WE HAVE YOUR BEST INTERESTS IN OUR HEART AND WE WILL SEE THE PROJECT THROUGH FROM START TO FINISH TO THE HIGHEST STANDARDS WHAT EVER YOUR PROJECT IS !

USING THE PATTERN THAT'S SHOWN ABOVE FOR DEVELOPING SEVERAL IDEAS FOR MANY BODY MODIFICATIONS USING THE SAME MOLD. THE MOLDS WE BUILD CAN SERVE MANY DIFFERENT FUNCTIONS. WHEN DONE THIS MOLD WILL BE ABLE TO MAKE OVER 6 DISTINCTIVE DIFFERENT CARS THAT ARE ON THE DRAWING BOARD BY USING INSERTS, TRIMMING, STRETCHING OR SHORTEN | WE MAINLY WORK WITH COMPOSITES BUT THE PATTERNS CAN BE MADE OF MOST ANYTHING, METAL, WOOD, CARDBOARD, PAPER, CLOTH, FOR EXAMPLE. WE DO REPAIR AND RESTORE CARS MADE OF METAL AND OF-COURSE WE ALSO BUILD CARS FROM SCRATCH USING OLD SCHOOL METAL BENDING PROCEDURES. Currently not accepting any repair work at this time. |